3D Printing in Medicine: in recent years 3D printing in medicine took a massive leap. Check out our analysis of where this exciting field stands today!

Dr. Bertalan Mesko, PhD

13 min | 7 November 2023

Key Takeaways

3D printing in healthcare shows enormous promise for revolutionizing medical equipment production, drug creation, and personalized medical services, with examples including cost-effective prosthetics and bespoke implants.

The pharmaceutical industry is embracing 3D printing with FDA approvals for 3D-printed drugs and the development of personalized medication, indicating a significant shift in drug manufacturing and distribution.

Despite the enthralling sci-fi imagery and futuristic scenarios often associated with 3D printing, the current state of this technology does not yet permit the printing of fully functional human organs. The vision of “printing” organs on demand for transplants, though actively pursued in research, is still a goal on the horizon rather than a present-day reality.

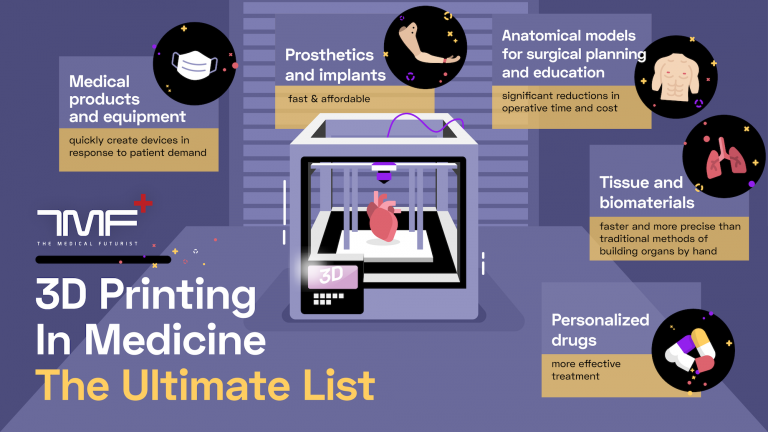

3D printing has demonstrated huge potential for the future of medicine in the previous years, and its development is unstoppable. See the impressive list of 3D-printed healthcare materials and medical equipment below!

How does 3D printing in medicine work?

3D printing in medicine is part of the innovative process called additive manufacturing, which means producing three-dimensional solid objects from a digital file. How the technology works, we explained in our article on bioprinting here.

As technology evolves, researchers work on various solutions. For example, engineers from the University of Buffalo have created a novel technology that speeds up the printing process itself. What’s remarkable about this particular hydrogen-based technology is that it’s way faster than previous 3D printing methods. Like, up to 50 times faster.

3D printing in medicine and healthcare could revolutionise drug creation and the production of medical equipment. It could also offer new methods for practicing medicine, optimising supply chains, and proposing cheaper and way more personalised medical services. Let’s see the most promising examples!

Personalised medical equipment

It is a well-known fact that medical equipment is expensive. The global medical devices market size was valued at USD 512 billion in 2022 and is projected to grow to USD 780 billion by 2030. Thus, 3D printing splints, medical models used before surgeries, or other necessary means for healing could save vast amounts of money. And there are already brilliant examples on the market of how to do it!

Ian McHale, a senior at the US Steinert High School, created a blueprint for producing finger splints. A low-end 3D printer can print his splint quickly and affordably, about 2¢ worth of ABS plastic in about ten minutes! For developing countries, where splints can often be ordered from overseas only in bulk, it could mean the cheapest solution for remote communities. At the same time, it could efficiently serve personal needs.

As for 3D-printed plaster casts, for the moment, these remain a distant hope. In theory, it sounds amazing; however, the technology still seems niche, facing several challenges before its mass adoption. We dedicated an entire article looking for the solutions and the companies providing them – find out more in Where Are 3D-Printed Casts?

But 3D printing in medicine can also be a lifesaver – as it saved the life of a baby in the U.S. Kaiba Gionfriddo was born prematurely in 2011 and suffered from tracheobronchomalacia – a congenital disability that causes the windpipe to collapse. He had a tracheostomy and was put on a ventilator––the conventional treatment. Still, Kaiba would stop breathing almost daily. His heart would stop, too. His caregivers 3D printed a bioresorbable device that instantly helped Kaiba breathe. After the operation, Kaiba’s trachea gradually reconstructed itself. His body reabsorbed the inserted splint. A year later, the tube was also removed without causing any harm.

Australian scientists 3D printed a set of microneedles for effective diabetes monitoring. These minimally invasive and minimally painful needles offer an effective way for continuous glucose monitoring – and open up the path towards personalised medicine and drug intake itself.

3D printing of medical equipment also played a significant role at the beginning of the COVID-19 pandemic. Urgent 3D production of especially personal protective equipment was literally saving lives for hospital personnel. In fact, 3D printing became a vital technology, supporting hospitals and frontliners. Community-based makerspaces offered freely accessible 3D blueprints helping the rapid response to the pandemic.

Models for surgical planning and education

3D printing can also help medical research and the outcome of complex operations and particularly challenging cases. Researchers in China and the US have both 3D-printed models of cancerous tumours to aid the discovery of new anti-cancer drugs and to better understand how tumours develop, grow, and spread. Bioprinted cancer models can even “mimic the 3D heterogeneity of real tumours.“

Researchers have also used scans of animal hearts to create printed models and then added flexible electronics on top of those models. The material can be peeled off the printed model and wrapped around the real heart for a perfect fit. The next step is to enhance the electronics with multiple sensors.

3D printing in medicine can be used to print organ models. These could also be helpful for patient education and pre-operative planning for surgeons. Scientists are using a combination of MRI and ultrasound imaging along with 3D-printing technology to help doctors prepare for fetal surgeries. With the 3D printed model, doctors can more easily identify potential obstacles and reduce the risk of surgery on babies with spina bifida, a congenital disability.

Another example is Schiner 3D Repro GmbH‘s Digital Anatomy 3D printer. The device can help simulate anatomies and pathologies with ultra-realistic 3D printed models, reducing the need for human and animal cadavers, ensuring high repeatability and acceleration across the design validation process.

Prosthetics and implants

Globally, over 30 million people need mobility devices such as prosthetics, while 80 percent of the world’s amputees do not have access to modern prosthetics. However, creating traditional prosthetics is very time–consuming and destructive, which means that any modifications would destroy the original moulds. In collaboration with Autodesk Research and CBM Canada, researchers at the University of Toronto used 3D printing to quickly produce cheap and easily customisable prosthetic sockets for patients in the developing world.

NGOs like Refugee Open Ware and Not Impossible were helping people in need with 3D printing in medicine. They created 3D-print prosthetics for refugees from war-torn areas. Not Impossible, for example, took 3D printers to Sudan in 2013, where the chaos of war has left many people with amputated limbs. The organisation’s founder, Mick Ebeling, trained locals to operate the machinery, create patient-specific limbs, and fit these new, very inexpensive prosthetics.

Personalised medical implants could also be 3D printed. This is especially important in complex and rare cases. Back in 2014, Dutch surgeons replaced the entire top of a 22 year–old woman’s skull with a customised printed implant made from plastic. The patient was suffering from a rare condition that caused the inside of her skull to grow extra bone, which squeezed her brain. The growth was discovered after she reported severe headaches and then lost her sight and motor control. If untreated, the extra bone would have killed her.

A novel 3D printing technique makes it possible to create astonishingly small and complex biomedical implants. Engineers and biomedical scientists at RMIT University in Australia created a ‘reverse’ 3D printing, versatile enough to use medical grade materials off-the-shelf. “The approach involves printing glue moulds that can then be filled with biomaterial filler. Once the mould is dissolved away, the biomaterial structure remains. Excitingly, the technique uses standard 3D printers, such as those now commonly even found in high schools, and PVA glue as a printing material.” Imagine the possibilities of this achievement!

3D Printing biomaterials

3D printing in medicine is a powerful tool for tissue engineering. No matter whether it is about blood, bones, heart, or skin. It is the technology that lets your jaw drop and scares the hell out of you at the same time when you first encounter it.

Blood vessels

Researchers at Harvard University were the first to use a custom-built 3D printer and a dissolving ink to create a swatch of tissue that contains skin cells interwoven with structural material that can potentially function as blood vessels in the future. The vasculature network enables fluids, nutrients, and cell growth factors to be perfused uniformly throughout the tissue.

As a next step, Korean engineers have created implantable 3D printed blood vessels and successfully implanted them into a rat. With the process, they hope to develop functioning artificial blood vessels needed to cure cardiovascular diseases.

Bones

Professor Susmita Bose of Washington State University modified a 3D printer to bind chemicals to a ceramic powder creating intricate ceramic scaffolds that promote the growth of the bone in any shape. It helps hip and knee replacements last longer by developing a body-friendly calcium phosphate-based coating for the implant materials. Once integrated, the coated implants are expected to last longer – possibly doubling the life of cemented implants. Researchers, in the meantime, started using sea coral or graphene and ceramics to create bone-like structures with 3D printing.

And using a novel method at the University of New South Wales in Sydney, Australia, doctors can create new bone tissue during surgery exactly where it is needed. “We can go directly into the bone where there are cells, blood vessels and fat, and print a bone-like structure that already contains living cells, right in that area”, – said Associate Professor Kristopher Kilian, who co-developed the technology in the university statement.

Heart valve

Jonathan Butcher of Cornell University has 3D printed a heart valve possessing the same anatomical architecture as the original valve. It will soon be tested on sheep. He used a combination of cells and biomaterials to control the valve’s stiffness. Butcher believes bioprinting will gain much more traction in the tissue engineering and biomedical community over the next five years, potentially becoming the standard in complex tissue fabrication.

Replicating human ears/noses

Lawrence Bonassar of Cornell University used 3D photos of human ears to create ear molds. The molds were then filled with a gel containing bovine cartilage cells suspended in collagen, which held the shape of the ear while cells grew their extracellular matrix.

Canadian scientists have printed synthetic noses for skin cancer patients. The printing used real human nose cartilage cells, donated by people having nose jobs, with collagen-based hydrogel. The nose job requires surgery, though, while Chinese scientists started research on mice printing the ear directly inside the animal.

And more recently, experts in France have grown a woman a new 3D-printed nose on her forearm after she lost hers to cancer.

“The operation involved ear, nose and throat experts as well as plastic surgery teams at the Toulouse University Hospital and the Claudius Regaud Institute and took place at the Toulouse-Oncopole University Cancer Institute. They said that they managed to successfully re-vascularise the patient’s nasal cavity, connecting the blood vessels by performing microsurgery.” She stayed in the hospital for 10 days and was on antibiotics for 3 weeks, and now she is doing very well.

Synthetic skin

In 2017, James Yoo at the Wake Forest School of Medicine in the US and researchers at the University of Madrid developed the prototype of a 3D printer that can create synthetic skin. It is adequate for transplanting patients who suffered burn injuries or have other skin issues. It may also be used in research or the testing of cosmetic, chemical, and pharmaceutical products.

A significant step forward for skin grafts and burn victims is the development of living skin. Researchers at the Rensselaer Polytechnic Institute developed a method to 3D-print living skin along with blood vessels.

Synthetic organs

When talking about 3D-printed organs, people tend to think of a machine that can create readily available, implantable human organs. However, the reality is far from this optimistic image.

Researchers worldwide are working on possible solutions: Organovo successfully bioprinted liver tissues already in 2014. They then seemed to be 4-6 years away from printing liver parts for transplantation. Together with the Murdoch Children’s Research Institute, Organovo even created miniature human kidneys in the lab.

Bioprinted organs could also be used in the pharmaceutical industry to replace animal models for analysing the toxicity of new drugs. Technological solutions like BioAssemblyBot we wrote about earlier and entirely new methods that can lead to patient-specific heart tissue printing will eventually lead to success: industry leaders expect a breakthrough in about a decade. In an interview for our Patreon site, Erik Gatenholm, CEO of CELLINK, said, “we will see fully functioning organs within the next decade or so.”

The future of pharma: 3D printed drugs

In 2015, the FDA approved the first-ever drug made by 3D printers, and in 2021, the second such medication received approval. Chinese pharmaceutical company Triastek, Inc. has received Investigational New Drug (IND) clearance from the FDA for its first 3D printed drug product, T19, which is designed to treat rheumatoid arthritis.

The latest major milestone happened in 2023 when the first clinical trial with a 3D-printed drug in Europe in the pediatric field was launched. The 3D printer used for the study produces medicines in semi-solid and chewable forms, which are personalised to each child based on their weight and clinical characteristics, as a collaboration between the Pharmacy Service at Vall d’Hebron University Hospital, the University of Santiago de Compostela, and the company FabRx.

Fantastic news for the industry as it opens up a range of opportunities to bring the supply chain to the next level.

In this live Q&A, Dr. Meskó from The Medical Futurist and Alvaro Goyanes, the Co-Founder and CEO of FabRx answered all the questions about 3D printed medicine, tissues, personalized drugs, customized prosthetics, casts, and 3D printed medical devices

3D printing of multiple medicines on a single pill, known as a polypill, is already possible. In 2020 FabRx released the first pharmaceutical 3D printer to manufacture personalised medication. ‘M3DIMAKER’ can print personalised medicine real fast – about 28 pills/minute. Imagine how fast the distribution of medication could be with a 3D printer in pharmacies! Or imagine how different our attitude towards pharmacies would be if we could print out pills at home.

Leave a Reply