CICI ZHOUANESTHESIOLOGY, CARDIOLOGY, CRITICAL CARE, MATERIALS, MEDICINE, NEWS, PUBLIC HEALTH

With the rise of COVID-19 cases throughout the United States, one of the biggest concerns is the potential shortage of ventilators for patients who have severe viral pneumonia. A team at the University of Minnesota has designed a mechanical ventilator that is inexpensive and made of easy to obtain materials.

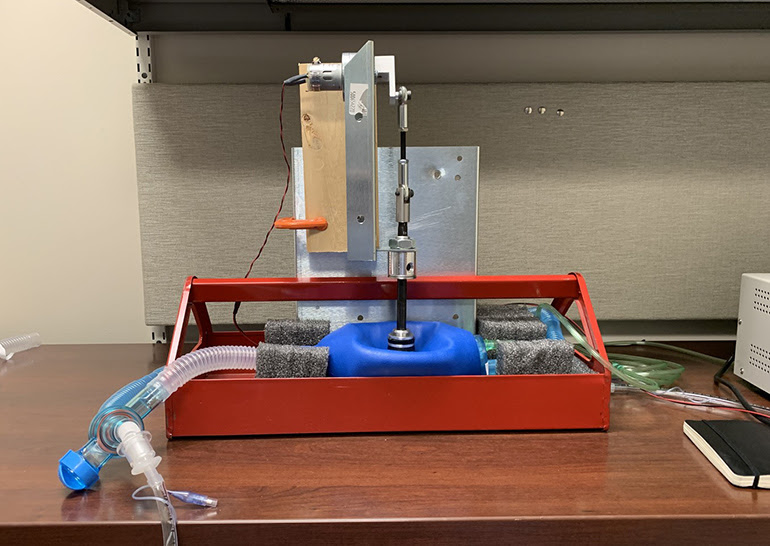

Unlike traditional ventilators, the Coventor does not require pressurized oxygen. The device consists of a frame and mechanical actuator that compresses a traditional ambulatory ventilation bag (aka Ambu bag or bag valve mask), which is connected to the patient’s endotracheal tube and is used to pump either external compressed oxygen or ambient air.

Frame and mechanical actuator to stabilize and compress a commercially available ambulatory ventilation bag connected to the patient’s endotracheal tube and external compressed oxygen, or if oxygen is not available, ambient air.

The finished device is about the size of a cereal box, and the frame itself can be metal stamped, 3D printed, or made with modified consumer goods. Currently, ventilators made by the development team will ship from Minneapolis, Minnesota.

The device was conceived and originally designed by Dr. Steve Richardson, an anesthesiology fellow at the University of Minnesota. It is a result of collaboration between the University and local manufacturing, electronics, and medical device companies. With the collaboration, the development team touts that they can acquire components and assemble thousands of ventilators per week to start.

“The reason that we’re here today is that somebody needed this ventilator that we’re making, yesterday,” said Richardson said in a video created by the development team. “This allows those patients who would otherwise not have an opportunity to survive, to survive. It gives people a chance.”

Leave a Reply