By Ben Coxworth

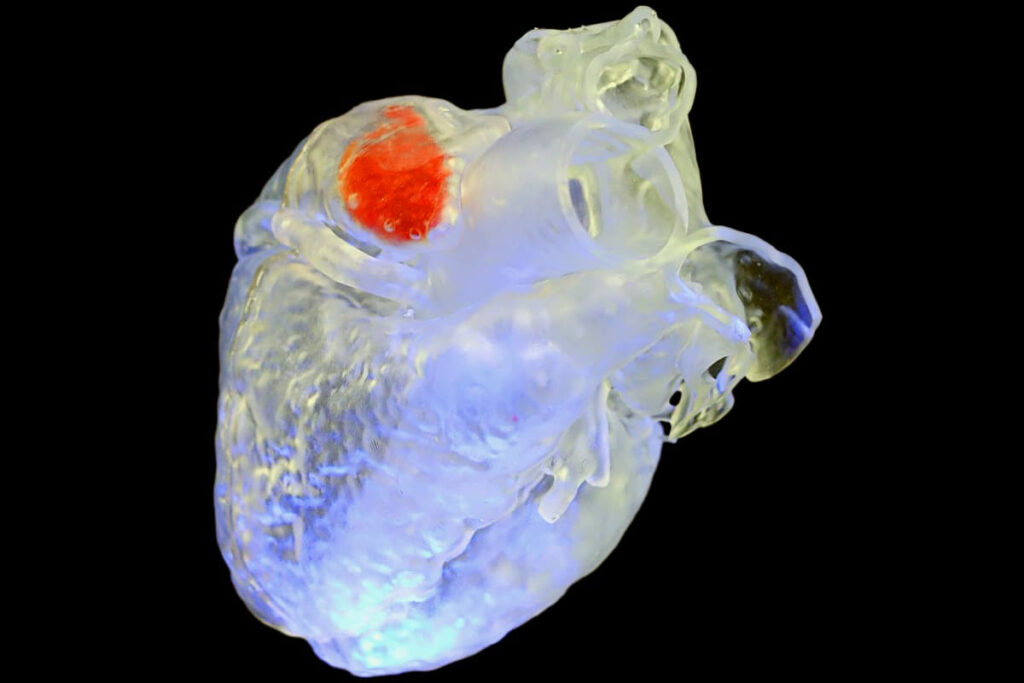

A solidified sono-ink structure (red) printed inside a heart model

Alex Sanchez, Duke University; Junjie Yao, Duke University; Y. Shrike Zhang, Harvard Medical School

In order to keep surgeries minimally invasive, it would be great if implants could be injected into the body in liquid form, then solidified once in place. Well, a new ultrasound-based 3D printing process may one day make that very thing possible.

The most common type of 3D printing involves building three-dimensional objects by depositing successive layers of viscous material that subsequently hardens. Another established method of 3D printing, known as volumetric printing, involves shining beams or patterns of light through the transparent top and sides of a container, inside of which is a photosensitive gelatinous resin.

Wherever that resin is exposed to the light, it polymerizes (solidifies) – the rest of the resin in the container remains a gel. By moving the light source around, so it reaches different parts of the resin, it’s possible to gradually build up a very detailed three-dimensional object.

One of the limiting factors of volumetric printing is the fact that for the light to reach its target, the container and the resin have to be transparent. Because human skin and biological tissue are nearly opaque, light can only reach a few millimeters through them. This means that in its current form, the technique can’t be used to build implants within the body.

With this limitation in mind, scientists from Duke University and Harvard Medical School invented a new sound-based technique called deep-penetrating acoustic volumetric printing, or DAVP. Instead of a photosensitive resin, it utilizes a biocompatible sonicated “ink” – known as sono-ink – which is formulated to heat up and then solidify when it absorbs pulses of ultrasound.

That viscous ink could conceivably be injected into the part of the body where an implant was required, then exposed to deep-reaching ultrasound waves delivered by a strategically focussed external probe. Once the implant itself had polymerized into the desired form, any leftover ink could be removed from the body using a syringe.

Depending on the intended application, the sono-ink can be formulated to be long-lasting or biodegradable, and to mimic different types of biological tissue such as bone.

In this example, DAVP is used to close the left atrial appendage in a goat heart, which can reduce the risk of forming blood clots inside the heart

In this example, DAVP is used to close the left atrial appendage in a goat heart, which can reduce the risk of forming blood clots inside the heartJunjie Yao, Duke University; Shrike Yu Zhang, Harvard Medical School

In lab tests performed so far, the scientists have used the DAVP technology to seal off a section of a goat’s heart (as would be required when treating nonvalvular atrial fibrillation), repair a bone defect in a chicken’s leg, and print chemotherapy-drug-dispensing hydrogels inside liver tissue.

“Because we can print through tissue, it allows for a lot of potential applications in surgery and therapy that traditionally involve very invasive and disruptive methods,” said Duke’s Assoc. Prof. Junjie Yao, who led the study along with Harvard’s Assoc. Prof. Y. Shrike Zhang and postdoctoral research fellow Xiao Kuang. “This work opens up an exciting new avenue in the 3D printing world, and we’re excited to explore the potential of this tool together.”

A paper on the study was recently published in the journal Science.

Sources: Duke University, American Association for the Advancement of Science via EurekAlert

Leave a Reply